Mining Industry

Mining construction

Mining

Mining construction refers to the engineering works required for mineral resource extraction, including infrastructure development for open-pit and underground mines, tunneling, orebody preparation, ventilation systems, drainage works, haulage system installation, and safety engineering. Its objective is to provide a reliable foundation for safe, efficient, and economical mining operations.

Star product

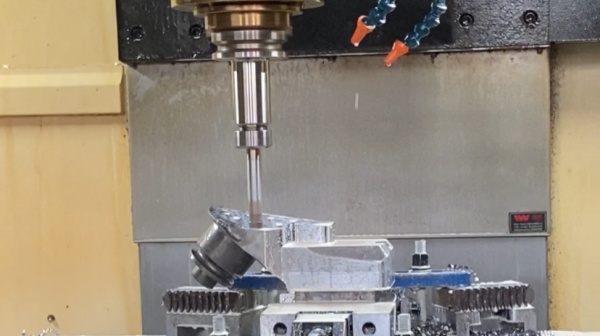

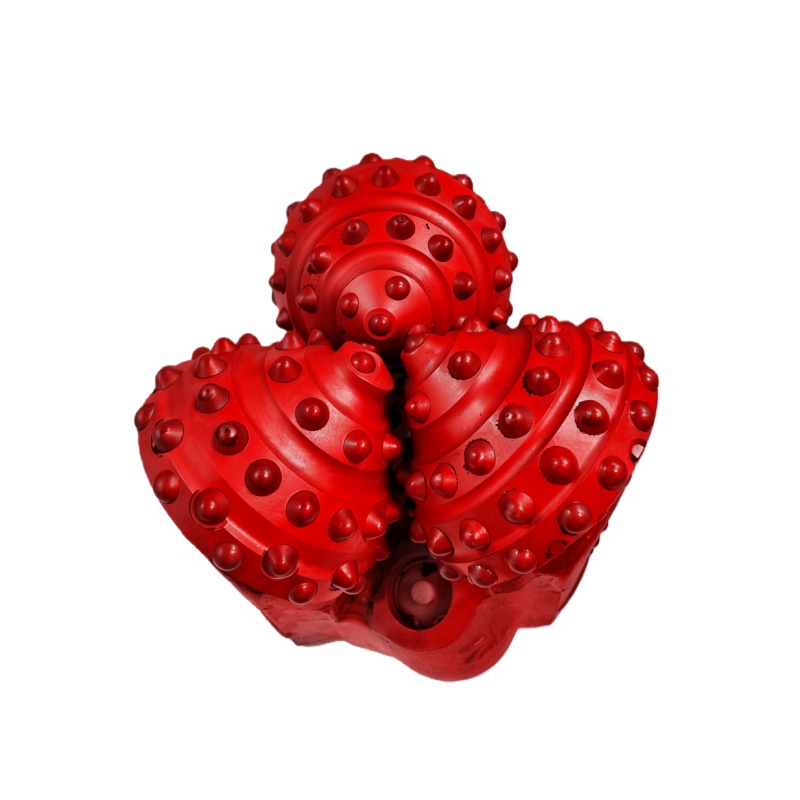

Mining Tricone Bit

Used in mining exploration, open-pit blast holes, anchor holes, and explosive charge holes.

Advantages: Cost-effective, versatile, suitable for both air and mud drilling conditions.

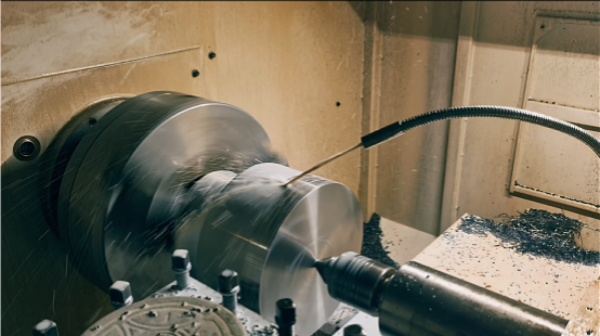

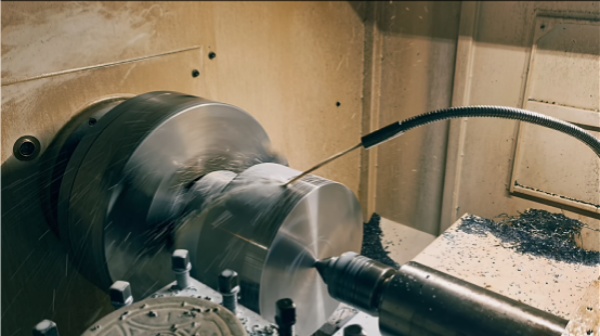

Mining PDC Bit

Used in coal mines, metal mines, and non-metallic mineral exploration, as well as anchor holes and blast holes.

Requirements: High wear and impact resistance in complex formations containing sandstone, shale, and coal seams.

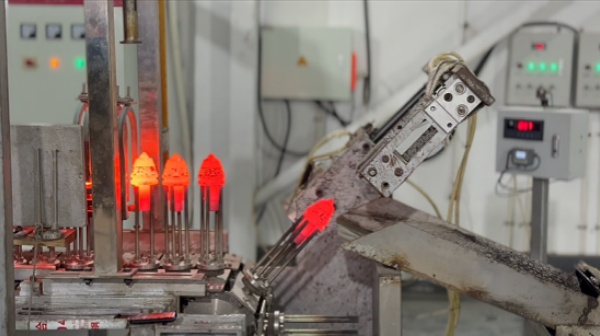

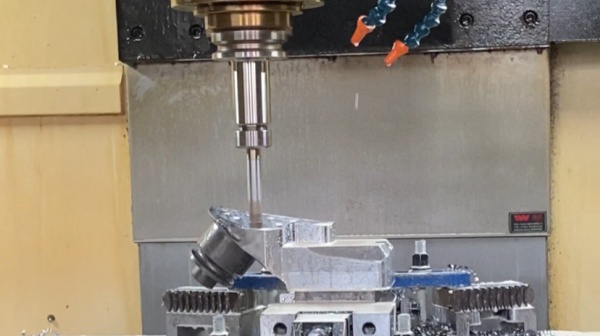

Mining picks

Mining picks are made from a high-strength alloy steel body paired with a premium tungsten carbide tip (WC-Co). The steel body is forged, quenched, and tempered for toughness, while carbide grades such as YG8–YG15 ensure exceptional hardness, wear resistance, and impact strength. During manufacturing, the carbide tip is securely attached by silver brazing or high-frequency welding, followed by surface treatments like sandblasting and anti-corrosion coating, as well as strict hardness and weld-quality inspections. These picks provide outstanding wear resistance, sharp cutting ability, strong impact endurance, and extended service life, reducing equipment load and improving cutting efficiency. They are widely used in coal mining, metal and non-metal mining, roadheader cutting drums, tunneling operations, and TBM auxiliary cutting, making them essential consumable tools in mining and underground construction.