HDD Tools

HDD

Horizontal Directional Drilling

Trenchless construction is an engineering method that allows underground pipelines and utilities to be installed, repaired, or replaced without extensive surface excavation. It is widely used in areas where open-cut excavation is impractical—such as roads, rivers, railways, and urban infrastructure. The method is known for its environmental friendliness, minimal disturbance, and short construction period.

HDD is the most widely used trenchless method. It creates a curved bore path underground through pilot drilling, reaming, and pipe pulling. It is commonly used for installing gas pipelines, power conduits, water supply lines, and telecommunication cables.

Star product

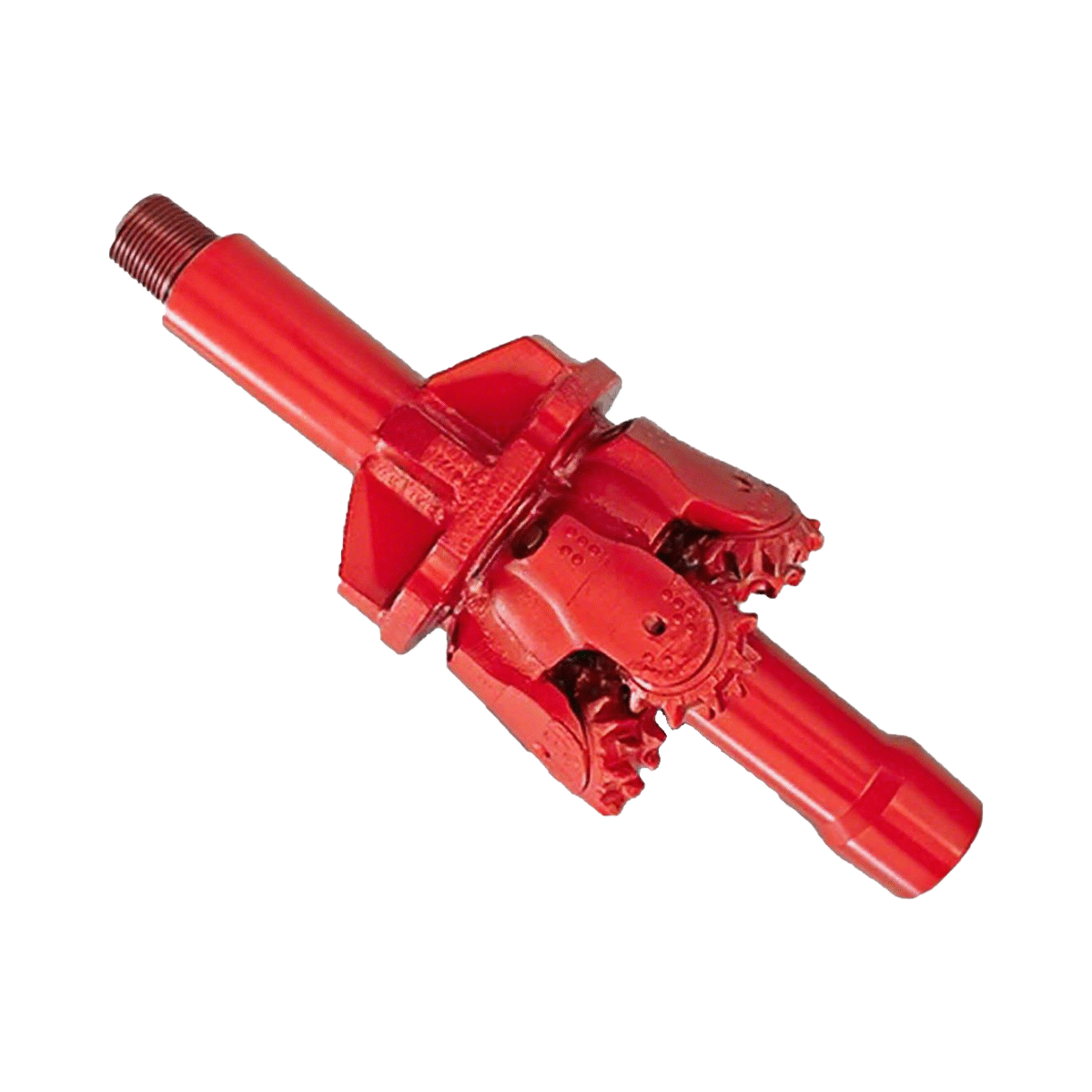

Directional Tricone Bit

Mainly used in directional drilling operations.

Ideal for oil, geothermal, and complex formation drilling, requiring high stability and trajectory control.

_副本-1.jpg)

HDD PDC Bit

Used for Horizontal Directional Drilling (HDD) projects, such as crossing roads, rivers, and pipeline installation. High impact resistance, good steerability, stable deviation control, and low risk of bit sticking.

Tricone Reamer

Suitable for medium-hard to hard formations such as sandstone, limestone, and basalt.

Widely used in:

Oil and geothermal well hole enlargement

HDD (Horizontal Directional Drilling)

Large-diameter water wells and mine ventilation holes

PDC Reamer

Ideal for soft to medium-hard formations such as mudstone, sandstone, shale, and limestone.

Commonly used for:

HDD back reaming

Water well and geothermal well hole enlargement

Mining and geological drilling

High penetration rate, long service life, no moving parts, and low maintenance cost.

Flow-through Reamer

Used during drilling to maintain borehole gauge, clean the hole, and prevent wall contraction.

Commonly applied in oil, geothermal, and engineering drilling as a stabilizing reaming tool.

Features: Compact structure, smooth chip evacuation, and dual reaming-stabilizing functions.

HDD drill rods

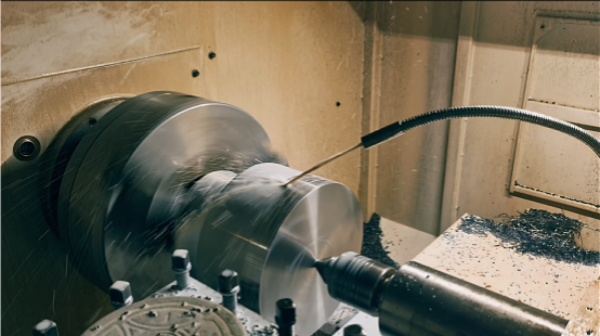

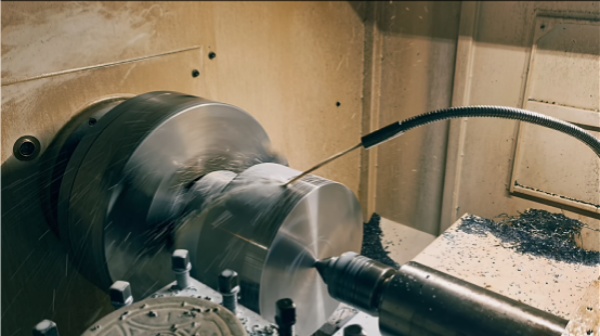

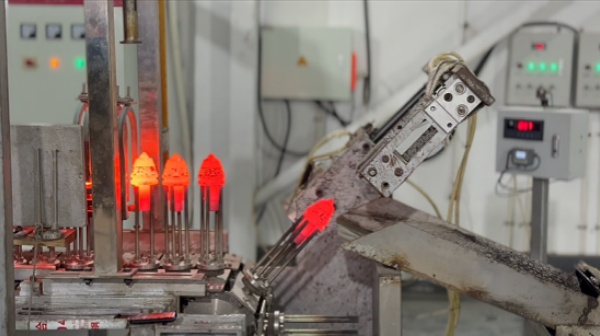

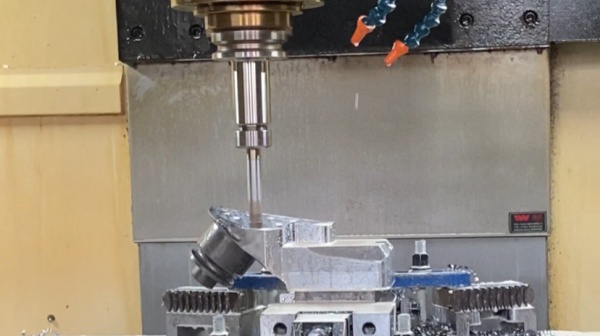

HDD drill rods are manufactured from high-strength alloy structural steels such as 42CrMo or 4145H, providing excellent tensile strength, torsional capacity, and fatigue resistance. CNC friction welding ensures a strong and reliable bond between the tube body and tool joints, while the joints undergo carburizing, quenching, and full heat treatment to achieve superior hardness and wear resistance. Additional anti-corrosion coating enhances durability in slurry-filled and wet-soil environments. HDD drill rods offer high torque transmission, strong bending resistance, stable steering accuracy, and long service life, effectively reducing the risks of rod breakage and joint failure. They are widely used in Horizontal Directional Drilling (HDD) operations for power and communication conduits, natural gas and water pipelines, municipal crossings, and road or railway trenchless installations. As the core component for steering, reaming, and pullback stages, HDD drill rods play a vital role in ensuring stable and efficient trenchless construction.

Stabilizer

1.Oil and Gas Drilling

Used in bottom hole assemblies (BHAs) to maintain wellbore trajectory, reduce dogleg severity, and prevent tool deviation.

2.Geothermal Drilling

Applied to stabilize the drill string and improve the drilling efficiency in high-temperature geothermal wells.

3.Water Well Drilling

Helps keep the drill bit centered, ensuring a straight and uniform borehole during water well construction.

4.Mining and Mineral Exploration

Used in exploration and production drilling to stabilize the drill stem and reduce borehole deviation in hard formations.

5.Horizontal Directional Drilling (HDD) / Trenchless Engineering

Ensures accurate borehole trajectory and minimizes deviation in non-vertical or horizontal drilling applications.