Geological Drill Rod

PRODUCT PARAMETERS

Material: R780 geology alloy steel pipe

Outer Diameter: 42mm, 50mm, 60mm (standard models)

Wall Thickness: 4.5mm, 5.5mm, 6.5mm (matched to exploration needs)

Standard Length: 1m, 2m, 3m (customizable for longer lengths)

Connection Type: API standard trapezoidal threaded connection

Applicable Formation: Soft soil, sandstone, shale and other conventional exploration formations

Operating Torque: ≥1200N·m

Surface Treatment: Anti-corrosion & rust-proof spraying + thread grease protection

Compliance Standard: Conforms to GB/T 16956 (Geological Drilling Drill Rod) industry standard

Description

Application: Geological exploration, mineral prospecting, and core drilling.

Types:

Round rods

Hexagonal rods (for percussive drilling)

Core rods (for coring applications)

Common Specs: Q, N, H, P series (e.g., NQ, HQ, PQ)

Material: 35CrMo, 30CrMnSiA

Features: Lightweight, flexible, and easy to guide.

FAQs

As a leading drill bit manufacturer, we specialize in six premium product lines tailored to diverse industrial needs: Tricone Bits (ideal for high-torque, multi-layer formation drilling), PDC Bits (engineered for efficient, long-lasting performance in soft-to-medium formations), Reamers (precision tools for borehole enlargement and stabilization), Stabilizers (critical for maintaining borehole trajectory and drill string stability), Drill Rods (high-strength, corrosion-resistant components for power transmission in drilling operations), and Picks (wear-resistant cutting tools optimized for mining and excavation applications). Each product is crafted with advanced materials and engineering to deliver exceptional durability and operational efficiency.

We partner with global, industry-leading logistics providers (including specialized freight carriers for heavy industrial equipment) to ensure reliable, timely delivery across markets. Our shipping network covers air, sea, and land freight—with dedicated handling protocols for oversized/heavy drilling tools—to support both bulk orders (e.g., containerized shipments for mining projects) and urgent, small-batch deliveries. We also offer end-to-end supply chain visibility, customs clearance support, and tailored logistics solutions to align with clients’ project timelines and regional operational requirements.

Our products adhere to stringent international standards (e.g., API, ISO) and are engineered to meet application-specific technical parameters:

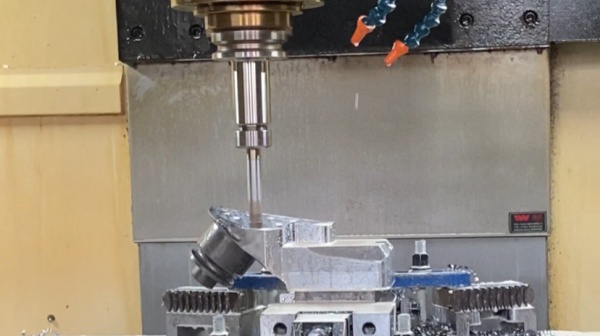

Drill Rods: Tensile strength (1200–1500 MPa), thread integrity (conforming to API 7-1 standards), and corrosion resistance (passivated or coated for harsh geological/water well environments).Custom technical specifications can be developed in collaboration with our R&D and engineering teams to address unique project challenges.

Tricone/PDC Bits: Hardness ratings (55–65 HRC for cutting structures), torque resistance (up to 15,000 ft-lbs), and temperature tolerance (up to 300°C for downhole stability).

Reamers/Stabilizers: Diameter precision (±0.05mm), material grade (high-alloy steel or tungsten carbide), and load capacity (up to 200 tons for heavy-duty mining applications).

Our streamlined, client-centric ordering process ensures clarity and efficiency:

Logistics & Delivery: Post-inspection, products are packaged per shipping standards; clients receive tracking details, and our team coordinates delivery to the designated location (with post-delivery technical support available upon request).

Consultation & Specification: Clients share project details (e.g., formation type, application, quantity), and our technical team recommends optimal product configurations.

Quotation & Confirmation: A detailed, customized quotation (including pricing, lead times, and technical documentation) is provided; clients confirm the order via formal purchase order.

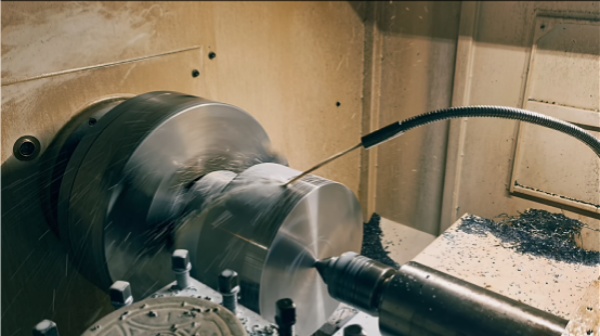

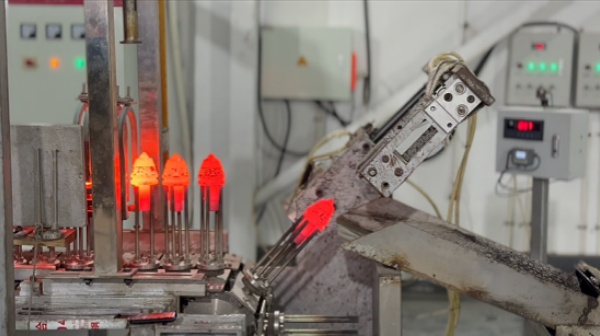

Production & Quality Assurance: Manufacturing commences with real-time progress updates; all units undergo multi-stage testing (hardness, dimensional accuracy, performance simulation) to meet our quality benchmarks.

REQUEST A QUOTE

-

Email: info@suredrill.com

-

WhatsApp: +86 15227566661

-

WeChat: +8615227566661